Purpose

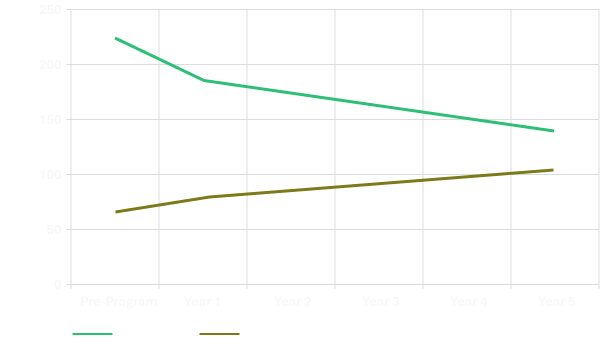

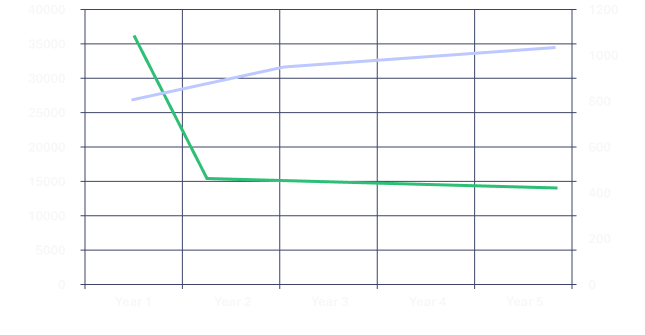

Improve Plant Performance: The program provides high-level reliability support services to improve the performance of the plant. It ensures that the equipment operates as specified.

Vendor Managed Inventory

Vendor Managed Inventory is a collaborative strategy that shifts the responsibility of inventory management from customer to vendor. In this system, Vendor take charge of managing customer inventories + Vendor will build inventory based on stock deficiencies to reduce downtime of critical asset.

Reduce Inventory and Operating Costs: The program helps to reduce inventory and operating costs. This is achieved by improving the reliability of the mechanical seals, thereby reducing the need for frequent replacements.

Key Outcomes of Vendor Managed Inventory

- Purchasers Excess stock levels and SAP Pricing values including a List of Obsolete Inventory items considering current Inventory shelf period and other factors such as operational suitability / previous and proposed technology upgrades & conversions / EHSS / process changes etc.

- Agreed stock levels by Tag no. and Criticality rating across all Inventory Levels such as complete units and number of spare kits

- Define Inventory Recalibration list based on existing inventory shelf period

- Proposed Suppliers Inventory [based on Agreed Stock – Purchasers stock deficiencies.]

- Purchasers Stock deficiencies by Tag & Criticality rating

- Assess and report the overall condition of the Purchaser Stock

- Create an Inventory interchangeability chart

- Implement a Stock ageing system

Unit Cost Vs Inventory Items

Inventory Coverage

Ensure Correct Application, Installation, and Operation

The selection, installation, and start-up of mechanical seals are critical processes. TESCO Engineering’s reliability program ensures correct application, installation, and operation. Mechanical seal reliability depends on precise application, installation, proper operation, and environmental controls.

Design Selection

TESCO Engineering's steadfast dedication to reliability through our comprehensive seal selection program, meticulously aligned with the latest guidelines outlined in API 682. Here's how we ensure and perform seal selection to meet these standards, emphasizing a meticulous approach to gap analysis and improvement

-

Adherence to API 682 Guidelines

Our program is structured to align closely with the latest edition of API 682 guidelines, ensuring compliance with industry best practices and standards.

-

Gap Analysis for Continuous Improvement

We conduct thorough gap analyses to identify areas for enhancement within our seal selection processes, enabling us to constantly refine and improve our practices.

-

Focused Design Selection

Our approach emphasizes focused design selection, ensuring that mechanical seals are meticulously chosen based on a holistic consideration of equipment characteristics, application specifics, operating conditions, and leak rate objectives.

-

Holistic Consideration of Factors

We understand that successful seal selection goes beyond just meeting basic requirements. We meticulously consider various factors such as equipment characteristics, application specifics, and operating conditions to ensure optimal performance and reliability.

-

Commitment to Performance

At TESCO Engineering, we're committed to delivering superior performance through our seal selection process. By aligning with API 682 guidelines and conducting detailed gap analyses, we ensure that our seals not only meet but exceed expectations in terms of reliability and effectiveness.

Root Cause Analysis

The program often includes a root cause analysis to identify the contributing factors that result in critical seal failures.

By identifying these causes, application reliability as well as seal lifetime can be improved

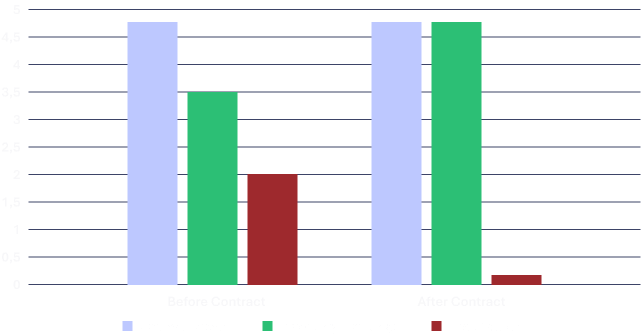

Bad Actor Improvement

- Identification of Bad Actors

- Root Cause Analysis (RCA)

- Definition of aims and Introduction of Improvements

- Training and Supervision

- Progress Monitoring and Documentation

-

Speed

Seal material and Profile

-

Temperature

Type of plymer

-

Application

Equipment type and operation

-

Media

Seal Material based on chemical

-

Pressure

Pressure and duty cycle

Condition Monitoring

Managed by cutting-edge, sophisticated software, our Reliability Program integrates advanced condition monitoring strategies to ensure optimal performance throughout the entire seal lifecycle. Below is an overview of the key components of our program:

-

Continuous Monitoring

We prioritize ongoing condition monitoring to track the health and performance of mechanical seals at every stage of their life cycle.

-

Integration with Reliability Programs

Our approach seamlessly integrates with existing reliability programs, allowing for a synergistic combination of strategies to maximize efficiency and effectiveness.

-

Utilization of Various Monitoring Concepts

We leverage a diverse range of condition monitoring concepts to tailor our approach to the specific needs of each seal, ensuring a customized and optimized maintenance plan.

Perform Visual Audit

Collect Incomplete Equipment Data

Perform Equipment Performance Testing

Responsibilities

-

S/N Activity Description Responsibility 1 Witnessing of Seal failure TESCO Engineering 2 Mechanical and Electrical isolation, Removal of insulation and decontamination and purging Purchaser 3 Removal of failed mechanical seal Purchaser 4 Refurbishment of failed mechanical seal TESCO Engineering 5 Installation Checks as per check list Performed by Purchaser / Witnessed by TESCO Engineering 6 Installation of Mechanical seal Performed by Purchaser / Witnessed by TESCO Engineering 7 Mechanical Seal pressure static test Performed by Purchaser / Witnessed by TESCO Engineering -

S/N Activity Description Responsibility 1 Installation pump at location Purchaser 2 Seal system piping & reservoir flushing Purchaser 3 Seal System heat exchanger cleaning Purchaser 4 Instrument calibration Purchaser 5 Mechanical seal drive collar torquing and removal of setting plate Performed by Purchaser / Witnessed by TESCO Engineering 6 Barrier fluid refilling TESCO Engineering 7 Static Test Performed by Purchaser / Witnessed by TESCO Engineering 8 Condition monitoring TESCO Engineering -

S/N Activity Description Responsibility 1 Monitoring Seal System Level, Pressure, Temperature, Flow TESCO Engineering 2 Providing required Barrier fluid Purchaser 3 Barrier fluid Refilling TESCO Engineering 4 Performing LLF survey TESCO Engineering 5 Pump bearing bracket oil filling Purchaser 6 Monitoring Equipment Vibration Purchaser -

S/N Activity Description Responsibility 1 Providing access to Purchaser inventory Purchaser 2 Inventory Audit TESCO Engineering 3 Monthly Purchaser inventory report Purchaser 4 Quarterly TESCO Engineering inventory report TESCO Engineering 5 Inventory interchangeability Chart TESCO Engineering

Partner with the Industry Leader

Need innovative engineering solutions? Reach out to TESCO Engineering for state-of-the-art products and expert support in the petrochemical and specialized industries.

Request a solution